charpy impact test errors|charpy impact testing methods : trader For example, an operator might be consistently reading the scale too high, so that the distribution of errors is described by a rectangular distribution defined by (a,b), where a and b are both. . 16 de abr. de 2018 · A receita de bala de goma caseira fica igual a jujuba original industrializada e você pode usar para festa infantil ou até mesmo fazer para vender. A bala de goma caseira dura por até 3 meses, basta guarda-las em um local seco e arejado, não precisa deixar na geladeira. Rende cerca de 60 balas em tamanho normal.

{plog:ftitle_list}

WEB24 de set. de 2023 · 深入理解C语言内存流函数:fmemopen, open_memstream, open_wmemstream. 1. 引言. 在C语言中,我们通常使用 FILE * 指针来操作文件。. 但有时,我们可能需要在 内存 中创建一个流,而不是在磁盘上。. 这就是 fmemopen, open_memstream, 和 open_wmemstream 这几个函数发挥作用的 .

Learn how to troubleshoot and resolve some of the common problems or errors that can affect the accuracy and reliability of the Charpy impact test results.This procedure covers the evaluation of uncertainty in the determination of Charpy impact test energy and related quantities according to the European standard EN 10045: Metallic .The absorbed energy of a test material, measured using a Charpy impact machine, is often reported as the mean absorbed energy of a set of specimens. However, the sample mean doFor example, an operator might be consistently reading the scale too high, so that the distribution of errors is described by a rectangular distribution defined by (a,b), where a and b are both. .

Impact test can be used to choose a proper material for railway tracks and welded points. By observing the fracture surfaces, we can determine their mechanical properties of them and make .

The purpose of this recommended practice guide is to demonstrate how to determine the uncertainty associated with mean absorbed energy of specimens tested on a .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

the Charpy machine verification program. We explain some of the distributional subtleties associated with uncertainty and ultimately relate these to the ASTM limits. Key words: .ABSTRACT: This paper provides a broad overview of the progress in procedural improvements for Charpy impact testing. It includes a short summary of early developments, a discussion of .

charpy impact testing procedure

The Charpy impact test is particularly essential for materials used in parts that are subjected to strong impact or high pressure, such as those used in the power generation units and piping of nuclear power plants. . It is capable of .computing uncertainty. We assume the reader is somewhat familiar with the Charpy machine verifi cation program administered by the National Institute of Standards and Technology. Keywords: absorbed energy; Charpy V-notch; impact test; pendulum impact test; uncertainty; verifi cation testing 1. Introduction The absorbed energy of a test . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

Temperatura: Las propiedades de tenacidad de un material pueden variar con la temperatura. Algunos materiales pueden volverse más frágiles a temperaturas bajas. Procesamiento térmico: Los tratamientos térmicos, como el temple y el revenido, pueden alterar las propiedades de tenacidad del material. Conclusión. La prueba de impacto Charpy es una .

Background – Impact Testing Toughness is a measure of the amount of energy a material can absorb before fracturing. It becomes of engineering importance when the ability of a material to withstand an impact load without fracturing is considered. Impact test conditions were chosen to represent those most severe relative to the potential

Microprocessor-based display for accurate test results. Display for impact/absorbed energy and angle of the test specimen. Separate fixtures for Izod and Charpy test. Feather touch controls; Technical Specifications of Izod/Charpy tester (digital model) The release angle of the pendulum: 150 degrees. Capacity: Up to 21.68 Joules.NISTRecommendedPracticeGuide: ComputingUncertaintyforCharpyImpactMachineTestResults J.D.Splett, 1C.N.McCowan, 2H.K.Iyer, 1andC.-M.Wang . Charpy impact test's ability to detect an intentionally introduced defect in a tested sample is studied, involving exploitation of force-displacement data recorded during the test on reduced-size samples. For a defect localized within the notch plane, the results show that reduced-size samples allow for detecting a localized defect. .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .

The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a . Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance withThe Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. AfterKey words: absorbed energy; Charpy V-notch; impact test; pendulum impact test; uncertainty; verification testing 1. Introduction To indirectly verify a Charpy machine, a set of five Charpy verification specimens are tested on the machine of interest and the broken specimens are returned to NIST along with the test results.

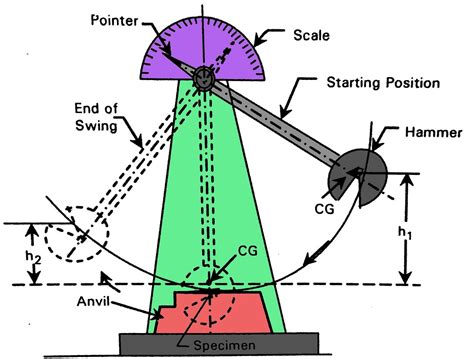

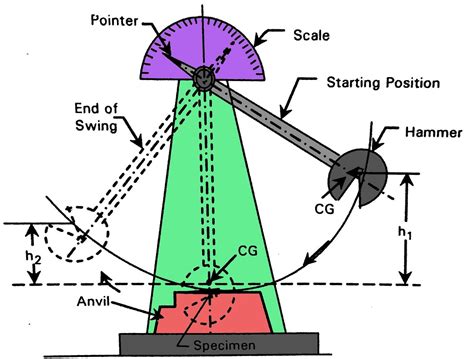

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch . Procedure for Charpy Impact Test Specimen Preparation: Prepare a sample with dimensions of 55 mm x 10 mm x 10 mm, featuring a 2 mm notch at the center.. Test Specimen: Elevate the simple pendulum to its initial position and verify the correct adjustment of the testing machine.; Begin by calibrating the Charpy machine -rotate the dial gauge to the maximum .Experiment 7: Charpy Impact Test Name: Om Prabhu Roll Number: 19D170018 Objectives: . Sources of Error: There is a time delay between taking out the specimen from the heater/liquid nitrogen and measuring its temperature. Hence, some heat . In its classic form, the machine has many sources of error, and it is difficult to compare results from different devices. Since the 1920s, researchers have been fitting out the pendulum’s wedge-shaped impact edge (called a .

The Charpy v-notch test remains an important quality assurance assessment quantifying a material’s resistance to sudden fracture from impacts.. Charpy impact test procedures, results analysis, and key advantages of this method versus alternatives like the Izod impact test. The standardized test measures the energy absorbed fracturing a notched specimen using a .

3. Uniaxial Strain Rate Corresponding to a Charpy Test. Very disparate values have been proposed in the literature for the equivalent uniaxial strain rate (ε ˙ e q) of a typical Charpy test, conducted with an impact speed between 5 m/s and 5.5 m/s. In Ref. , Server reports values of ε ˙ e q between 10 2 s −1 and 10 3 s −1 at general .

Figure 8 — Charpy vs Impact test Fracture modes. . Errors. In this test we assumed that other energy losses caused by friction and air resistance is zero. But actually it is not. There is a .Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of . Single piece pendulum plus integral base and anvil eliminate errors induced by loose parts. Specifications of this Impact Tester: Velocity: 0.1 to 5.1m/sec,Energy:0.2 to 359Joules, Data Acquisition: Instron .ssociated with the test result requires more consideration. The purpose of this document is to clarify the concept of uncertainty and to provide Charpy laboratories with a procedure for NIST Recommended Practice Guide: Computing Uncertainty for Charpy Impact Machine Test Resu J. D. Splett, 1 C. N. McCowan, 2 H. K. Iyer, 1 and C.-M. W 1

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3).The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, and microscope. It also outlines the step-by-step procedure for setting up and performing an impact test, which .

The purpose of this recommended practice guide is to demonstrate how to determine the uncertainty associated with mean absorbed energy of specimens tested on a Charpy impact machine. We assume that the Charpy machine has successfully met the requirements for both direct and indirect verification as described in the ASTM E 23, Standard .What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact test 1 Scope This document specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test

s7 edge screen drop test

s7 edge uag case drop test

Juninho Paulista. Osvaldo Giroldo Júnior (born 22 February 1973), known as Juninho or Juninho Paulista, [note 1] is a Brazilian former footballer who played as an attacking midfielder and is now the national team co-ordinator of the Brazil national football team. [4] During his professional career, he played for Brazilian clubs São Paulo .

charpy impact test errors|charpy impact testing methods